Inspection and inspection support by sound / vibration diagnosis | AnimoWaveBase

AnimoWaveBase®

Inspection and inspection support by sound / vibration diagnosis

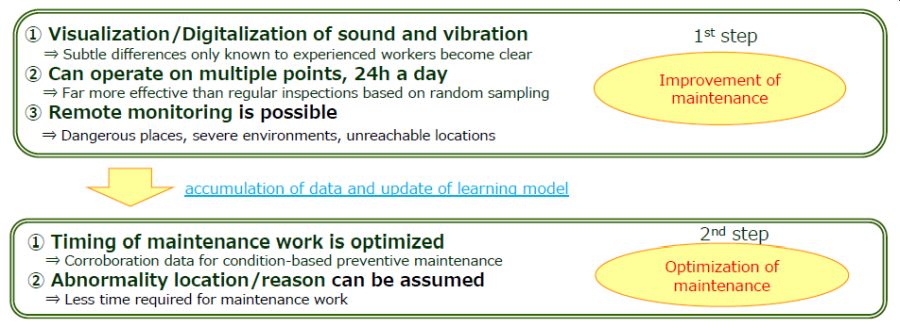

Visualize, digitize, and diagnose equipment status using sound and vibration information. Improve product quality and yield.

Inspection and inspection support by sound / vibration diagnosis

Visualize, digitize, and diagnose equipment status using sound and vibration information. Improve product quality and yield.

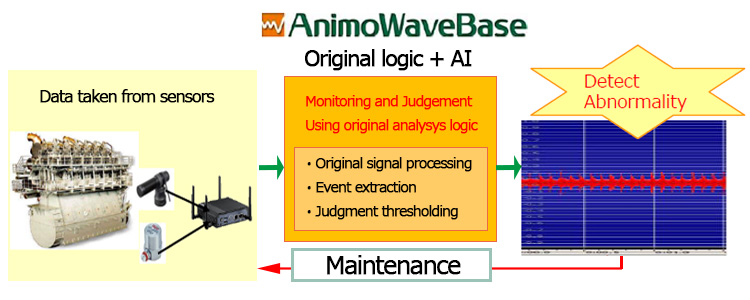

Acquisition and analysis of sound, vibration, and noise data using unique algorithms You can easily monitor the normal operation of your manufacturing equipment and diagnose failures.

Sound, Vibration and Artificial Intelligence

Failure prediction Error detection Remote monitoring Simplified maintenance

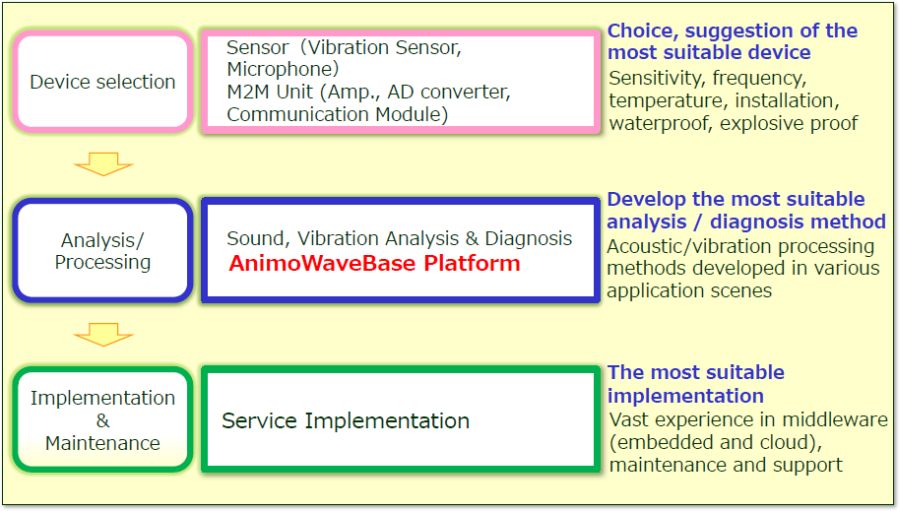

End to end solution from device selection to implementation & maintenance

Feature

Merit of AnimoWaveBase

Use case

Scene1

Enable easy maintenance, remote control, supervise and failure prediction in your factory!! Patrol inspection of multiple motors

Worker patrols the chemical plant analyzing acoustic data of 700 motors

| - Merit: | (1) quantitative analysis of sound (2) possible to record, store, and look back past operation data (3) able to analyze multiple targets with one device |

Scene2

Implement all workloads as the same level among each workers, Optimize Work flow and time and Improve Production accuracy! Condition monitoring of gear box

Defect of the decelerator cannot be detected by the change in running voltage or sound volume.

However, it can be detected by observing its vibration in details.

Preventive Maintenance of Chip mounter

Scene3

Supervise and Analyze 'Sliding Noise of the machine ' and Improve accuracy! Preventive Maintenance of Chip mounter

- Monitoring of Y axis sliding arm

- Calculation of the energy ratio of 1kHz 3kHz range frequency during motion/still

- Preventive maintenance based on the analyzed result